Welcome To HavenseeK Fishing Tackle

Custom Bass Fishing Rods: What Your Supplier‘s Engineer Considers

Written by Alex Chen – Senior Rod Design Engineer at Havenseek Fishing Tackle.

With 12 years of experience, I’ve led the R&D for over 50 series of bass fishing rods, providing OEM/ODM solutions for more than 30 brands worldwide. My job is to turn an angler’s need into a perfectly balanced tool.

Have you ever received a batch of bass fishing rods that looked flawless on the outside, only to find them lacking that critical “feel” on the water? The sensitivity is muted, the backbone feels vague, and you’re left wondering if you just paid for a fancy-looking carbon stick rather than a precision instrument. This frustrating disconnect often stems from a fundamental gap in understanding between what you ordered and what your fishing rods supplier engineered.

The truth is, a world-class bass fishing rod is not merely assembled; it is designed from the blank up for a specific purpose. As an engineer inside a fishing rods factory, my mission is to bridge that gap. This article is your backstage pass to the R&D lab and production floor. I’ll reveal the key engineering decisions that transform raw materials into performance tools. You’ll learn not just what goes into a premium rod, but why it matters for your fishing success or product line. By the end, you’ll have an insider’s checklist to evaluate any fishing rods factory and the precise questions to ask your supplier to ensure you get a rod built for performance, not just for a price point. Let’s dive into the mind of a rod engineer.

What’s Inside: Your Guide to Bass Rod Engineering

- 1. The Blueprint: Matching Rod Design to Bass Fishing Techniques

- 2. The Heart of Performance: Materials Science in Modern Bass Rods

- 3. Precision Tuning: From Blank to Finished Masterpiece

- 4. Inside a Top-Tier Fishing Rods Factory: The QA That Makes the Difference

- 5. Conclusion & Your Next Step

- 6. Frequently Asked Questions (FAQs)

Part 1: The Blueprint: Matching Rod Design to Bass Fishing Techniques

The journey of a great bass fishing rod begins not with carbon fiber, but with a question: “What problem is this rod meant to solve?” At Havenseek, we operate on a “Toolbox Philosophy.” Just as you wouldn‘t use a sledgehammer to drive a finish nail, you shouldn‘t use a heavy flipping stick for finesse drop-shotting. Every design parameter is a deliberate choice aimed at optimizing for a specific fishing technique.

Understanding the “Toolbox” Mentality

Bass fishing is incredibly diverse. The gear and techniques for punching thick mats are worlds apart from those needed for skipping a wacky rig under a dock. A credible fishing rods supplier understands this intimately. We start every project with a detailed technique profile. Is this rod for:

- Power Fishing: Flipping, Punching, Heavy Cover?

- Finesse Applications: Drop Shot, Neko Rig, Shaky Head?

- Reaction Bite Lures: Crankbaits, Spinnerbaits, Topwater?

- All-Around Versatility: Jigs, Texas Rigs, Swimbaits?

This initial classification drives every subsequent engineering decision. Our internal product matrix maps over 15 distinct bass techniques to specific rod architectures, ensuring we never build a “generic” rod that performs poorly at everything.

Critical Design Parameters Decoded: Action, Power, and Taper

These three terms are often misunderstood, but they are the holy trinity of rod design. Here’s what they truly mean from an engineer‘s perspective:

- Power (Rod Weight): This refers to the rod‘s overall resistance to bending—its “backbone.” It’s primarily determined by the diameter and wall thickness of the blank and the stiffness of the carbon fiber used. Think of it as the rod‘s lifting strength.

- Action (Taper): This describes where the rod bends. A “Fast” action bends primarily in the top 25-30% of the blank, while a “Moderate” action bends deeper into the middle.

The Synergy: Power and Action work together. A Heavy Power, Fast Action rod is a brutal tool for pulling big bass from cover. A Medium-Light Power, Extra-Fast Action rod is a sensitive wand for detecting subtle bites with light line.

The Technique-Driven Design Table

The magic happens when we map these parameters to techniques. Here’s a simplified look at our internal logic:

| Fishing Technique | Recommended Power | Recommended Action | Primary Engineering Goal |

|---|---|---|---|

| Flipping/Punching | Heavy (H) / Extra-Heavy (XH) | Fast / Extra-Fast | Maximize lifting power for instant hooksets in heavy cover. Stiff midsection is critical. |

| Jig & Worm (1/2 oz+) | Medium-Heavy (MH) | Fast | Balance sensitivity for bite detection with ample backbone for driving thick hooks. |

| Crankbaits (deep) | Medium (M) / MH | Moderate | Deeper bend to keep tension on treble hooks and prevent throw-offs. Forgiveness is key. |

| Drop Shot / Ned Rig | Medium-Light (ML) / M | Extra-Fast | Ultra-sensitive tip to transmit the lightest bites, with enough lower-section power to control fish. |

Why This Matters for You: When you discuss a custom bass fishing rod project with your fishing rods factory, you must move beyond just “I need a 7‘3″ MH Fast.” Discuss the primary lures, line class, and cover type. A good engineer will ask these questions. Their ability to translate your needs into these core parameters is the first sign of a competent supplier.

Part 2: The Heart of Performance: Materials Science in Modern Bass Rods

Once the blueprint is set, we select the materials. This is where the science becomes tangible and where cost versus performance trade-offs are most acutely felt. The choice of carbon fiber is the single most important decision in defining a rod‘s character.

Carbon Fiber 101: Beyond the “Tonnage” Hype

You’ll hear terms like “30-ton,” “40-ton,” or “IM8.” This refers to the modulus of the carbon fiber, a measure of its stiffness. Higher modulus fibers are stiffer and lighter.

The Reality Check: Higher modulus is not categorically “better.” It’s a tool.

- High Modulus (40T, 46T, 60T+): Incredibly stiff and sensitive. Transmits vibrations with stunning clarity. However, it is more brittle and has lower impact resistance. It’s also significantly more expensive.

- Standard Modulus (24T, 30T): More durable, forgiving, and impact-resistant. It has more “flex” and dampening, which can be desirable for certain techniques. It is far more cost-effective.

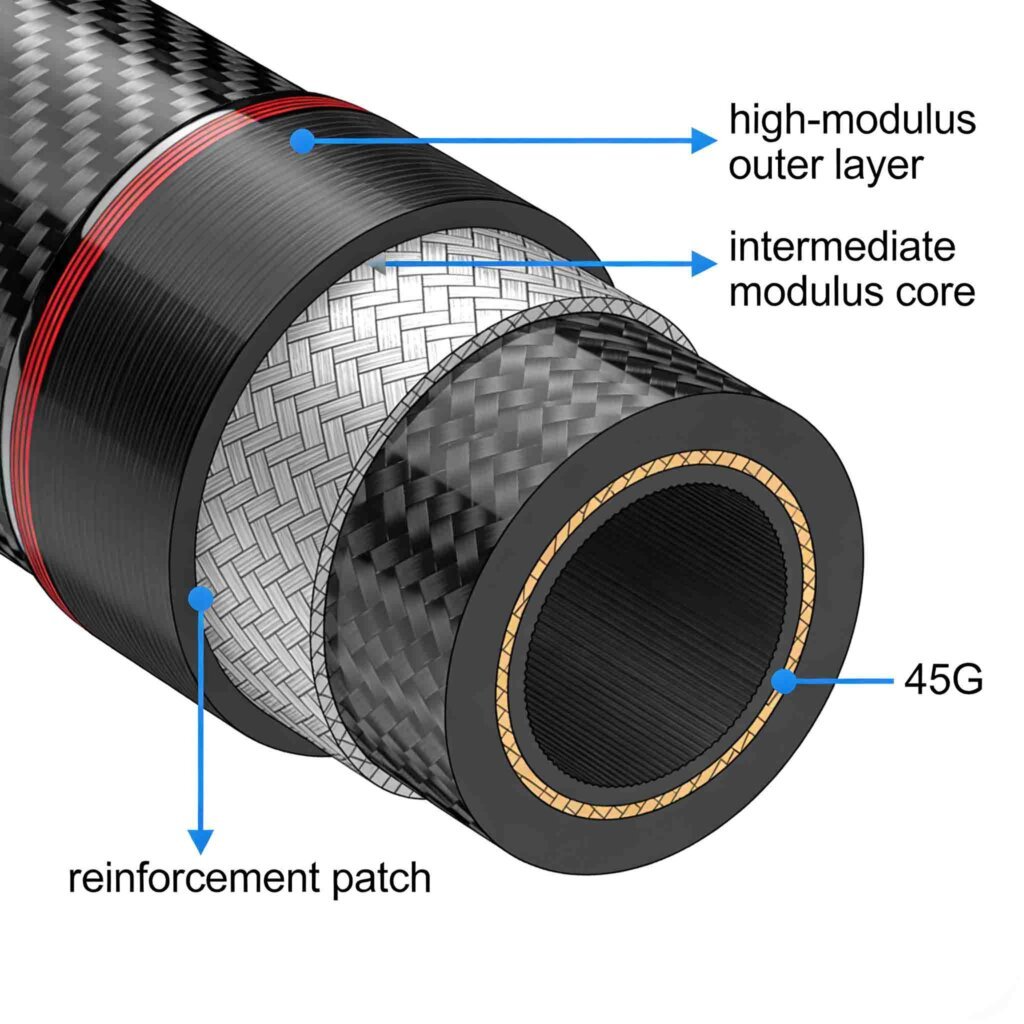

The Engineer‘s Secret: Hybrid Layups. At Havenseek, we almost never use a single type of carbon in a blank. We build with strategic layup schedules. For a sensitive yet durable jig rod, we might use:

- 60T carbon in the tip section for ultimate bite detection.

- 40T carbon in the midsection for a powerful, responsive backbone.

- 30T carbon in the butt section for durability during high-stress lifting and leverage.

This “triaxial” approach lets us engineer a specific bend curve and strength profile that a single-modulus blank cannot achieve. It optimizes performance while managing cost and durability. A fishing rods factory that only talks about using “high-modulus carbon” without context may be oversimplifying or misleading you.

The Art of Layup: How a Factory‘s Expertise Turns Carbon into “Feel”

Carbon fiber arrives as a woven cloth or uni-directional sheets. How we layer and orient these sheets—the layup—is where engineering becomes artistry.

- Uni-Directional (UD) Carbon: Fibers run in a single direction. This provides tremendous longitudinal stiffness (critical for sensitivity and hook-setting power) but less torsional (twisting) stability.

- Bidirectional / Woven Carbon: Fibers are woven at 0° and 90° angles. This improves torsional stability and durability but can add slight weight and dampen sensitivity.

The Precision Process:

- Pattern Cutting: Carbon sheets are cut into specific trapezoidal patterns that will form the rod‘s taper.

- Rolling & Curing: The sheets are rolled onto a tapered steel mandrel at precise angles (often ±45° for outer layers to handle torsion). The resin-saturated blank is then cured in a controlled oven.

- Mandrel Removal: The hardened blank is extracted, now a hollow, tapered carbon tube.

The Critical Variable: Fiber Orientation. By changing the angle at which the carbon fibers are wound, we control the rod‘s behavior. Fibers aligned with the rod‘s length (0°) maximize sensitivity and power. Fibers wrapped on a bias (±30°, ±45°) increase torsional rigidity and durability. A premium bass fishing rod uses a complex, multi-layer schedule of UD and biased layers to create a blank that is sensitive, powerful, and durable.

Part 3: Precision Tuning: From Blank to Finished Masterpiece

A perfectly designed and cured blank is just a component. The final 30% of performance—and 100% of the user‘s tactile experience—comes from the precision tuning in the finishing and assembly process. This is where a great fishing rods supplier separates from a good one.

Guide System Engineering: Minimizing Friction, Maximizing Casting

Guides are not just rings to hold the line; they are a high-performance casting and retrieval system.

- Frame & Ring Material: This choice balances weight, durability, and heat dissipation.

- Frames: Stainless steel is standard and durable. Titanium frames are 40% lighter and corrosion-proof, crucial for reducing overall tip weight for sensitivity.

- Rings: Hardened stainless steel is basic. Aluminum Oxide (Alconite) is a great upgrade for smoothness and durability. Silicon Carbide (SiC) and TZ (Titanium Zirconia) are top-tier, offering exceptional hardness, smoothness, and heat dissipation to protect modern braided lines.

Ask Your Supplier: “What guide spacing system do you use, and how is it optimized for this rod‘s specific action and line class?” A technical answer here indicates deep engineering.

The Human Interface: Handle Design for Ergonomics and Fatigue Reduction

The handle is your direct connection to the rod. Its design profoundly affects comfort, control, and fatigue over a long day.

- Material Choice:

- Cork: Traditional, lightweight, warm to the touch, and provides excellent grip even when wet. Higher-grade cork is more uniform and durable.

- EVA Foam: Durable, highly consistent, and cost-effective. Provides good cushioning. High-density EVA offers a more premium feel.

- Shape & Length – It‘s Not One-Size-Fits-All:

- A long, straight handle is ideal for two-handed casting techniques.

- A shorter handle with a pronounced “pistol grip” curvature is engineered specifically for flipping and pitching, allowing for precise, short-range accuracy and powerful one-handed hooksets.

The Final Touch: Weight Balancing and Sensitivity Calibration

Two final, often-overlooked steps can transform a good rod into a great one.

- Weight Balancing: A rod that is tip-heavy will feel cumbersome and cause fatigue. We often add a small, precisely measured counterweight inside the butt cap or adjust the reel seat position. The goal is to bring the balance point just in front of the reel, making the rod feel lighter and more maneuverable in hand.

- Sensitivity Calibration & Consistency Check: This is the “artisan” step. We conduct what we call the “tap test” and “blind feel test.”

- Tap Test: An engineer gently taps the tip of the finished rod on a hard surface and feels the vibrations transmitted through the handle. This checks for blank imperfections or glue issues that deaden sensitivity.

- Blind Feel Test: Experienced testers handle multiple samples of the same model blindfolded, assessing weight, balance, and “blank feel” for consistency.

Part 4: Inside a Top-Tier Fishing Rods Factory: The QA That Makes the Difference

Design and assembly are futile without ruthless quality assurance. A trustworthy fishing rods supplier has a QA protocol that is integrated into every step, not just a final inspection. At Havenseek, our 12-point QA process is what turns our engineering into your confidence.

More Than Just a Checklist: Our 12-Point Quality Assurance Protocol

Quality is baked in, not inspected in. Here is a snapshot of our critical control points:

| QA Stage | Checkpoint | Purpose & Standard |

|---|---|---|

| 1. Incoming Material | Carbon Cloth Roll Certification | Verify modulus, resin content, and weave consistency against spec sheets. |

| 2. Mandrel Prep | Mandrel Taper & Surface Inspection | Ensure mandrel is perfectly smooth and to spec; any flaw transfers to the blank. |

| 5. Blank Straightness | Laser Straightness Check | Rotating the blank under a laser line to detect and correct any curvature before cutting. |

| 8. Load Testing | 100% Static Load Test | Every blank is subjected to a load equal to 2x its rated line class to check for structural integrity. |

The “Durability vs. Sensitivity” Trade-off: How We Find the Sweet Spot

This is the eternal challenge in rod design. Maximizing sensitivity often means using thinner, higher-modulus blanks, which can be more fragile. Maximizing durability means thicker walls and more material, which adds weight and dampens feel.

Our Engineering Solution is Multi-Faceted:

- Hybrid Layups (As discussed): Placing tougher, lower-modulus carbon in high-stress areas.

- Reinforcement Patches: Strategically adding small carbon or aramid fiber patches at stress concentration points.

- Progressive Wall Thickness: Using computerized mandrel design to create blanks that are thicker-walled at the butt and progressively thinner toward the tip.

- Real-World Torture Testing: We subject prototype rods to brutal cycles in our test lab and put them in the hands of our sponsored anglers who fish 200+ days a year.

The Result: A rod that feels incredibly sensitive for its power class but won‘t fail under normal—and even some abnormal—fishing conditions. This balance is the hallmark of a mature fishing rods factory.

Conclusion & Your Next Step

Designing and building exceptional bass fishing rods is a symphony of materials science, mechanical engineering, and deep angling knowledge. It‘s about making intentional, informed choices at every step—from the initial technique blueprint to the final weight balance check.

As a buyer or brand, your power lies in asking the right questions. Move beyond specifications and catalogs. Engage your potential fishing rods supplier in a technical dialogue:

Your 5-Point Supplier Evaluation Checklist

- Ask “Why?”: Why was this specific taper chosen for this technique? Why this guide spacing?

- Request Layup Details: Can they explain the carbon moduli used in different sections of the blank? Do they use hybrid construction?

- Demand QA Transparency: What specific tests does every rod undergo? Do they have a static load test protocol?

- Request Samples for Feel: Ask to evaluate samples not just for cosmetics, but for balance, weight, and that intangible “blank feel.”

- Discuss Customization: A true partner will work with you to adjust parameters to match your exact vision.

At Havenseek Fishing Tackle, we are not just a fishing rods factory; we are a team of engineers and anglers obsessed with creating the perfect tool. We want you to understand what goes into your rods because an informed partner is the best partner.

Ready to Experience Engineering-Driven Design?

Get Your Free, No-Obligation Custom Rod Design Consultation & Quote in 12 Hours.

Let’s discuss your vision for the perfect bass fishing rods. Our engineering team will provide specific insights and a transparent proposal.

Request Your Free Engineering Consultation Now

Frequently Asked Questions (FAQs)

What’s more important in a custom bass rod, the blank material or the components?

The blank is the foundation—it defines the rod‘s soul. A premium blank with poor guides will still be sensitive and have a great action, but performance will be hampered. Excellent components on a poor blank create a nice-looking rod with mediocre feel.

The ideal is a synergistic design where a high-performance blank is matched with components that complement it. A good fishing rods factory will balance the investment between both.

How do I know if a fishing rods factory is using high-quality carbon fiber?

Direct certification is best but often confidential. You can infer quality by: 1) Asking for specifics: Can they name the carbon supplier? 2) Evaluating the finish: High-modulus blanks have a very fine, tight weave pattern. 3) The “tap test”: Gently tap the tip. A high-quality blank will produce a sharp, high-pitched “ping” and transmit the vibration clearly to your hand. A lower-grade blank sounds duller.

What is the minimum order quantity for custom bass fishing rods from your factory?

MOQs depend on the level of customization. For a fully custom design from a new blank, our typical MOQ starts at 500 pieces per model. For modifying an existing model, MOQs can be as low as 200-300 pieces. We also offer “semi-custom” programs from our extensive catalog with even lower thresholds. Contact us directly with your needs for an exact quote.

Can you match the action and feel of a popular brand’s rod model?

Yes, this is a common request for OEM/ODM clients. As experienced engineers, we can reverse-engineer the performance characteristics of a reference rod to create a functionally equivalent blank. We focus on matching the feel and performance, not infringing on intellectual property. This process requires a physical sample of the reference rod for analysis in our lab.

How long does development take for a new custom rod?

The timeline varies by complexity. A typical project from brief to shipped goods takes about 4-5 months. This includes: Concept & Specs (1-2 weeks), Blank Development & Prototyping (4-6 weeks), Prototype Evaluation & Refinement (2-3 weeks), and Pre-Production & Mass Production (8-10 weeks). Rushing this process is the biggest risk to final quality.

Further Reading & Resources

- The Ultimate Guide to Rod Blank Materials: Carbon, Glass, and Composites Explained – TackleTour

- Understanding Fishing Rod Guides and Tops: A Comprehensive Guide from Fuji – Angler’s Resource

- How It‘s Made: The Precision Process of Building a Graphite Fishing Rod – Sport Fishing Mag

© 2026 Havenseek Fishing Tackle

All rights reserved. This content is based on the professional experience of our engineering team and is intended for informational purposes to guide your purchasing and partnership decisions.