Welcome To HavenseeK Fishing Tackle

Inside a Fishing Tackle Manufacturer: Quality Secrets for Wholesalers

Written by Michael Chen – Head of Production & Quality Assurance at Havenseek Fishing Tackle. With 18 years on the factory floor, I’ve managed the production and quality protocols for more than 12,000 product lines, ensuring reliability for hundreds of fishing tackle wholesale businesses worldwide. This article pulls back the curtain on what truly matters in manufacturing.

Table of Contents

- Part 1: The Real Cost of “Good Enough” in Wholesale

- Part 2: The Science of Materials: Where Quality is Born

- Part 3: Engineering & Testing: The Crucible of Reliability

- Part 4: The Production Floor: Precision in Practice

- Part 5: Your Actionable Partner-Vetting Checklist

- Frequently Asked Questions (FAQ)

Let’s be brutally honest. If you’re in the fishing tackle wholesale business, you’ve likely faced this nightmare: the samples were perfect, but the main shipment is riddled with issues. Reels that grind, rods with inconsistent action, lures that lose their paint after three casts. Your customers complain, returns eat your profit, and your brand’s reputation takes a hit. You blame your fishing tackle supplier, but the root cause often lies deeper—in a fundamental misunderstanding of how quality is actually built, not just inspected.

This article is different. I won’t just tell you to “check quality.” Instead, I’m taking you inside the walls of a professional fishing tackle manufacturer. You’ll see the machinery, understand the tests, and learn the questions that separate true manufacturing partners from mere order-takers. Why is this worth your next 15 minutes? Because the insights here will fundamentally change how you source, vet, and collaborate with suppliers. This knowledge is your leverage—it will help you secure better margins, build a bulletproof brand, and sleep soundly knowing your supply chain is solid. This is the masterclass in sourcing that can transform your fishing tackle wholesale operation from a price-driven commodity game into a value-driven, sustainable business.

Part 1: Beyond Price Tag: Why Manufacturing Philosophy Dictates Your Wholesale Success

Before we touch a single material, we must confront a critical mindset shift. For a wholesaler, the true cost of poor quality is a hidden iceberg.

The Hidden Costs That Destroy Margins

It’s not just the cost of the defective unit. The real financial hemorrhage comes from:

- Logistical Nightmares: Reverse shipping, customs headaches for returns, and disposal fees.

- Service & Support Drain: Your team’s time spent managing complaints, processing returns, and appeasing angry customers.

- Brand Erosion: A single bad batch can lead to negative reviews that echo online for years, crippling customer acquisition.

- Lost Opportunity Cost: The inventory capital tied up in unsellable stock and the missed sales from customers who never return.

Choosing a fishing tackle supplier based solely on a 5% lower unit cost can easily incur 30%+ in hidden costs.

Factory vs. Manufacturing Partner: The Critical Distinction

Any workshop can assemble parts. A true fishing tackle manufacturer operates with a manufacturing philosophy—a proactive system obsessed with preventing errors, not just finding them. This philosophy is embedded in every process, from design to packaging.

Case in Point: The $0.15 Bearing Seal

Years ago, we analyzed returns for a popular spinning reel. A significant percentage failed due to saltwater intrusion corroding the main bearing. The “factory” solution was to use a standard rubber seal. Our engineering team, driven by a philosophy of “zero freshwater intrusion,” designed a dual-lip seal with a proprietary grease cavity. It cost $0.15 more per unit. The result? Returns for that failure mode dropped by over 98%. For our wholesale partners, this meant fewer headaches, happier end-customers, and a product they could confidently market as “saltwater-ready.” This is the tangible value of partnering with a manufacturer that thinks beyond assembly.

Part 2: The Science of Materials: Where Quality is Born

Exceptional gear starts with exceptional materials. This is the first and most crucial filter in assessing a fishing tackle manufacturer. Let’s decode the jargon.

Carbon Fiber & Composites: It’s All About the Layup

Not all “carbon fiber” rods are created equal. Performance is dictated by:

| Material Factor | What It Means | Question to Ask Your Supplier |

|---|---|---|

| Carbon Cloth Modulus (e.g., 24T, 30T, 40T, 60T) | Higher modulus means stiffer, lighter fibers. A blend is used for optimal balance of sensitivity, power, and durability. | “What is the modulus mix in your blank? Can you provide a spec sheet from your carbon fiber vendor?” |

| Resin System & Cure Process | The resin binds the fibers. High-grade, thermally cured resins create a stronger, more consistent bond than cheap air-dried alternatives. | “Is the blank thermally cured? What is the resin-to-carbon ratio?” |

| Roll-Wrapped vs. Sheet-Wrapped | Precision sheet-wrapping (using pre-cut carbon sheets) allows for more accurate spine alignment and consistent wall thickness than random roll-wrapping. | “Can you describe your blank winding process?” |

Metal Components: The Devil in the Details

From reel housings to hook points, metal quality is non-negotiable.

- Aluminum Alloys: For reel bodies, ask if it’s machined from solid bar stock (superior strength, precision) or die-cast (can have porosity, weaker). A good fishing tackle supplier will know the alloy series (e.g., 6061-T6).

- Stainless Steel: “Stainless” is not one material. Ask for the grade. 304 stainless is good for freshwater; 316 marine-grade stainless is essential for saltwater guides and screws.

- Gear Technology: High-end reels use brass or stainless steel gears, often cold-forged for denser, more durable grain structure than cut gears.

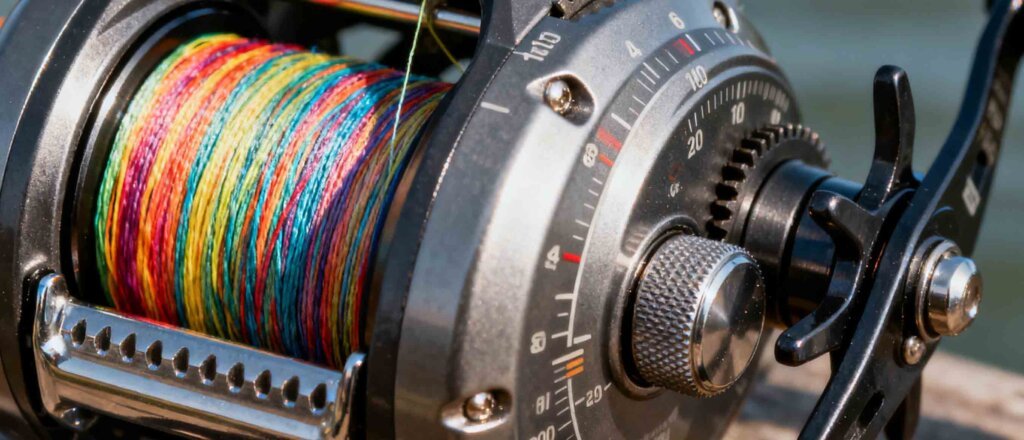

Close-up, detailed shot of different raw materials used in fishing tackle manufacturing: spools of carbon fiber cloth, metal alloy ingots, and high-grade resin containers, arranged in an industrial setting.

The foundation of quality: Premium raw materials like specific carbon fiber weaves and certified metal alloys are the starting point for any reputable fishing tackle manufacturer.

Part 3: Engineering & Testing: The Crucible of Reliability

This is where prototypes become dependable products. A manufacturer’s investment in R&D and testing is the clearest indicator of their commitment to your long-term success in fishing tackle wholesale.

Stage 1: Digital Validation (DVT)

Long before a mold is cut, sophisticated software simulates real-world stress.

- Finite Element Analysis (FEA): Software applies virtual forces to a 3D model of a reel handle or rod blank. It identifies potential weak points, allowing engineers to reinforce areas before production, saving thousands in tooling rework.

- Computational Fluid Dynamics (CFD): Used for lures and swimbaits to analyze and optimize hydrodynamics, ensuring the desired action right from the first prototype.

Stage 2: The Reliability Lab – Where Products Are Tortured

This is the heart of quality assurance. A credible fishing tackle manufacturer will have a dedicated lab with these standard tests:

- Salt Spray (Fog) Test (ASTM B117): Components are placed in a chamber that mists a concentrated salt solution for dozens or hundreds of hours. This accelerates corrosion, revealing weaknesses in plating, coatings, and material choices. A quality reel should withstand 72+ hours with minimal corrosion.

- Dynamic Load & Fatigue Testing: A machine repeatedly casts a weight or bends a rod thousands of times to simulate years of angler use, searching for material fatigue or joint failure.

- Drag Washer Endurance Test: Reels are mounted, and the drag is engaged at a set pressure for extended periods under heat, testing for consistency and degradation.

- Impact and Crush Tests: For rod tips and reel bodies, ensuring they can survive realistic bumps and crushes during transport or use.

A technician in a lab coat monitoring advanced testing equipment in a fishing tackle manufacturing quality control laboratory. The image shows a salt spray test chamber and a rod fatigue testing machine in action.

Reliability is proven, not promised. In-house testing labs with equipment like salt spray chambers and fatigue testers are the hallmark of a serious fishing tackle manufacturer.

Stage 3: The Ultimate Test – Real Anglers, Real Water

No machine can replicate the unpredictability of a angler. We maintain a network of field testers—from professional guides to weekend enthusiasts—who put pre-production samples through hell in various environments. Their feedback on ergonomics, performance in wind, and “feel” is invaluable final data before mass production.

Part 4: The Production Floor: Precision in Practice

Even the best design and materials can be ruined by sloppy assembly. This is where Standard Operating Procedures (SOPs) and meticulous process control make all the difference for a fishing tackle supplier.

SOPs: The Blueprint for Consistency

On a reel assembly line, every station has visual work instructions detailing exact steps, torque specifications for every screw (using calibrated torque drivers), and required lubricants. This ensures the 10,000th reel is identical to the first.

The QC Trinity: Catching Errors at Every Stage

- Incoming Quality Control (IQC): All raw materials and components from sub-suppliers are inspected against specifications before entering production. This stops bad batches before they consume labor.

- In-Process Quality Control (IPQC): Line supervisors and dedicated QC staff perform random checks on semi-finished products. For example, checking guide alignment on a rod before the epoxy cure.

- Final Quality Control (FQC): Every single finished product undergoes a final check. For a reel, this means checking drag smoothness, handle tightness, bail function, and visual appearance before packaging.

A focused assembly line worker at a clean, organized workstation, using a calibrated torque screwdriver to assemble a fishing reel, with clear SOP instructions visible in the foreground.

Consistency is king. Standardized assembly processes with calibrated tools and clear instructions ensure every unit that leaves the factory meets the same high standard.

The Unsung Hero: Tool & Die Maintenance

The molds that create plastic lure bodies or reel frames wear down over time. A professional manufacturer has a strict preventive maintenance schedule for all tooling. A worn mold produces parts with flash (excess plastic) or dimensional inaccuracies, leading to poor fit and finish. Ask about their mold maintenance program.

Part 5: Your Actionable Partner-Vetting Checklist

Now, transform this knowledge into power. Use this checklist when evaluating a new fishing tackle manufacturer or auditing your current one.

The Factory Tour: What to Look For (Beyond the Showroom)

Request to see, in this order:

- The Raw Material & IQC Warehouse: Is it organized? Are materials labeled with vendor and batch info?

- The Production Lines: Is the floor clean and organized (5S)? Are tools at each station? Do workers refer to SOPs?

- The QC Lab: Do they have the testing equipment we discussed? Is it being used, or is it dusty?

- The Tooling/Mold Storage Area: Are molds stored properly and labeled with maintenance dates?

The 8 Must-Request Documents

A transparent fishing tackle supplier can provide these:

| Document | Purpose |

|---|---|

| 1. Material Certificates of Analysis (COA) | Proof of carbon fiber modulus, metal alloy grades, etc. |

| 2. ISO 9001:2015 Quality Management System Certification | Independent audit of their process control system. |

| 3. Test Reports for Key Products | Salt spray, fatigue, drag test results from their lab. |

| 4. Factory Audit Report (e.g., by SGS, Bureau Veritas) | Third-party verification of social compliance and capacity. |

| 5. Product Liability Insurance Certificate | Protects you in the rare case of a product defect causing harm. |

| 6. Detailed QC Inspection Report Template | Shows you exactly how they inspect goods before shipment. |

| 7. Compliance Certificates (RoHS, REACH) | Ensures materials are free of restricted hazardous substances for your market. |

| 8. References from Existing Wholesale Clients | Speak directly to their current partners about reliability. |

Questions That Separate the Pros from the Amateurs

Ask these during your meeting:

- “Walk me through your process when a field tester reports an unexpected failure in a prototype.”

- “What is your standard sampling process between production batches to ensure consistency?”

- “How do you manage component traceability if we need to identify all products from a specific batch of bearings?”

Their answers will reveal their depth of process and problem-solving capability.

How Havenseek Embeds This System for Your Success

At Havenseek, we don’t just sell you products; we integrate our quality ecosystem into your fishing tackle wholesale operation. This means:

- Shared QC Protocols: We can customize AQL (Acceptable Quality Level) inspection criteria based on your specific market tolerance.

- Transparent Communication: You get direct access to production managers (not just sales reps) for real-time updates.

- Co-Development: We apply this entire quality-first framework to help you design and manufacture your own branded, differentiated products.

A metaphorical handshake between a wholesaler (represented by business documents and a globe) and a manufacturer (represented by blueprints and a precision gear), symbolizing a deep, trusting partnership.

The ultimate goal: A strategic partnership between wholesaler and manufacturer, built on transparency, shared standards, and a mutual commitment to quality.

Conclusion: Quality as Your Ultimate Competitive Advantage

The journey through a true fishing tackle manufacturer‘s world reveals a clear truth: quality is a system, not an accident. It is designed in, manufactured in, and validated at every step. As a wholesaler, partnering with a supplier that embodies this system is the single most powerful investment you can make in your business’s future. It transforms you from a commodity reseller, vulnerable to the cheapest bidder, into a value-driven brand manager with a reliable, profit-protecting supply chain. You gain the confidence to offer warranties, to market performance, and to build a loyal customer base. In the competitive world of fishing tackle wholesale, this knowledge—and the partnerships it enables—is your unbeatable edge.

Ready to Apply This Knowledge?

Stop guessing about your supplier’s capabilities. Let’s have a direct, technical conversation about your needs. As a next step, we offer two ways to experience the Havenseek difference firsthand:

Option 1: Request a Free, Fully-Documented Sample Kit. We’ll send you not just products, but the accompanying material certs and test reports for them.

Option 2: Download Our Comprehensive 2026 Product & Capability Catalog. It details our manufacturing processes, material specs, and private label options.Get Your Free Sample Kit or Catalog PDF Now

Direct inquiries from qualified buyers are prioritized and typically receive a detailed quotation within 12 hours.

Frequently Asked Questions (FAQ)

1. As a new wholesaler, what’s the minimum order quantity (MOQ) I should expect from a quality manufacturer?

MOQs vary by product complexity. For standard catalog items from a fishing tackle manufacturer like us, MOQs can start as low as 100-500 pieces per SKU to help you test the market. For custom or private label designs, MOQs are higher (often 1000+) due to mold and setup costs. A good fishing tackle supplier will work with you to find a feasible starting point.

2. How can I verify the test reports a supplier provides are authentic and not generic?

Ask for reports that are product-specific and batch-traceable. They should include your potential product’s model number, the batch/sample ID tested, dates, and the signature/stamp of the lab supervisor. You can also request a short video of your specific product sample undergoing a key test (like a drag test).

3. What’s the biggest red flag when visiting a potential fishing tackle manufacturer?

An inability or unwillingness to show you the entire process—especially the raw material storage, production floor, and QC lab. If the tour is confined to a lavish showroom and conference room, be very cautious. Transparency is the cornerstone of a trustworthy partnership.

4. We want to create our own branded line. Does a manufacturer’s quality system apply to custom projects?

Absolutely, and it’s even more critical. The entire framework—DVT, material selection, prototyping, staged testing—is precisely what ensures your custom design is viable, durable, and market-ready. A manufacturer without this system is merely guessing with your investment.

5. How do you handle quality disputes if a shipment has issues?

Clear protocols are key. At Havenseek, our FQC reports and batch tracking allow us to quickly identify the scope of any issue. Our terms outline a structured process: evidence submission, joint review (often via video call), and rapid resolution which can include replacement, credit, or re-work. The goal is to solve the business problem, not to debate it.

Further Reading & Resources

To deepen your knowledge on building a successful wholesale business, we recommend these articles:

Penn Authority 2025 Updates

13 Fishing Concept C3 2025